线性运动筛分机

针对大而粗糙的颗粒筛分需求提出的优良解决方案

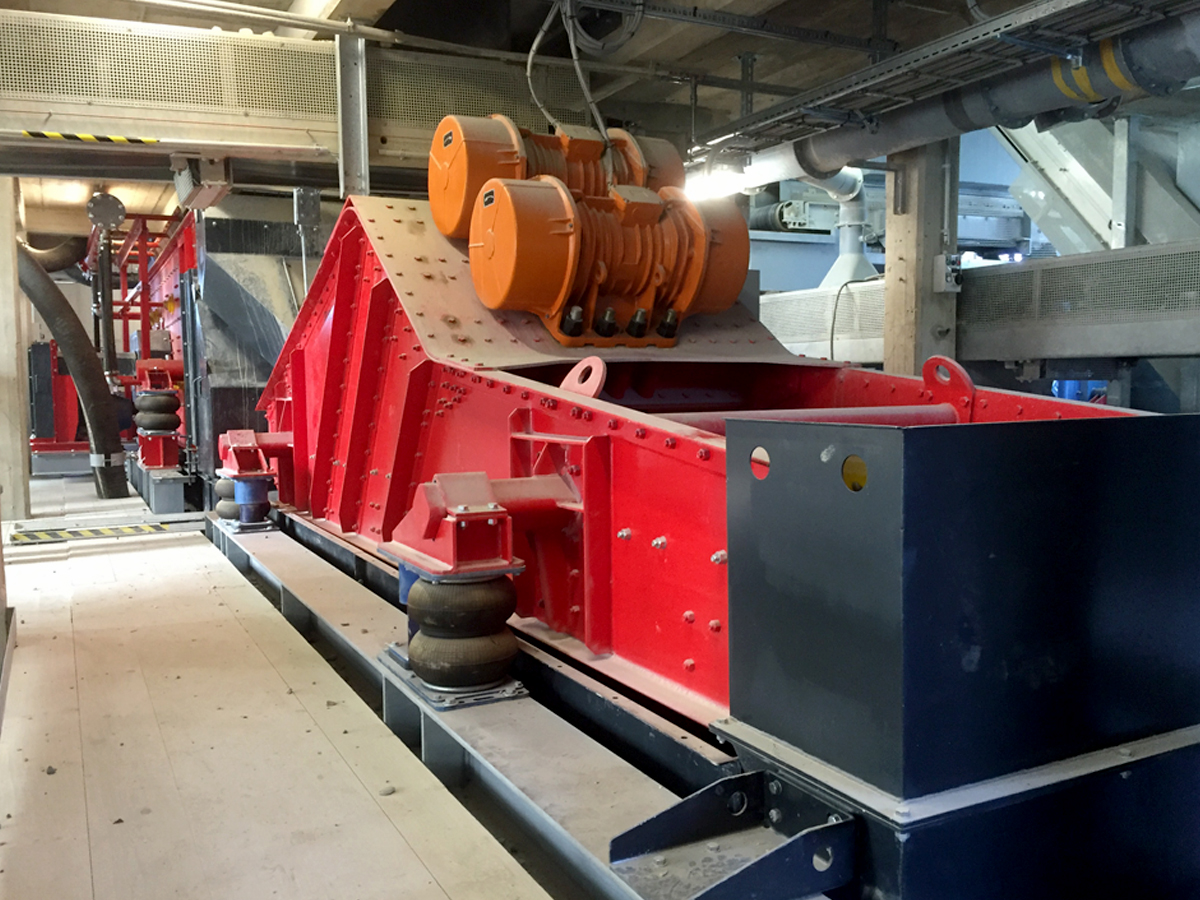

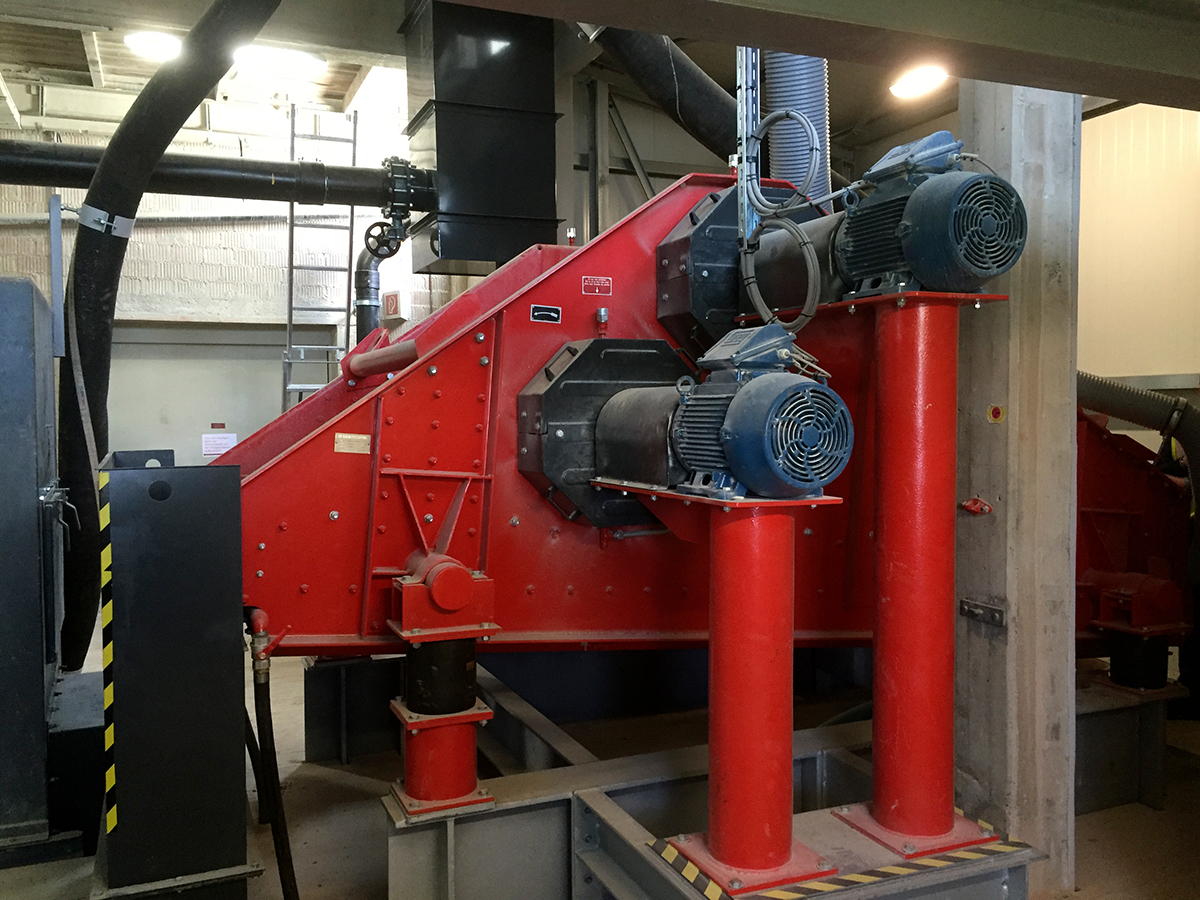

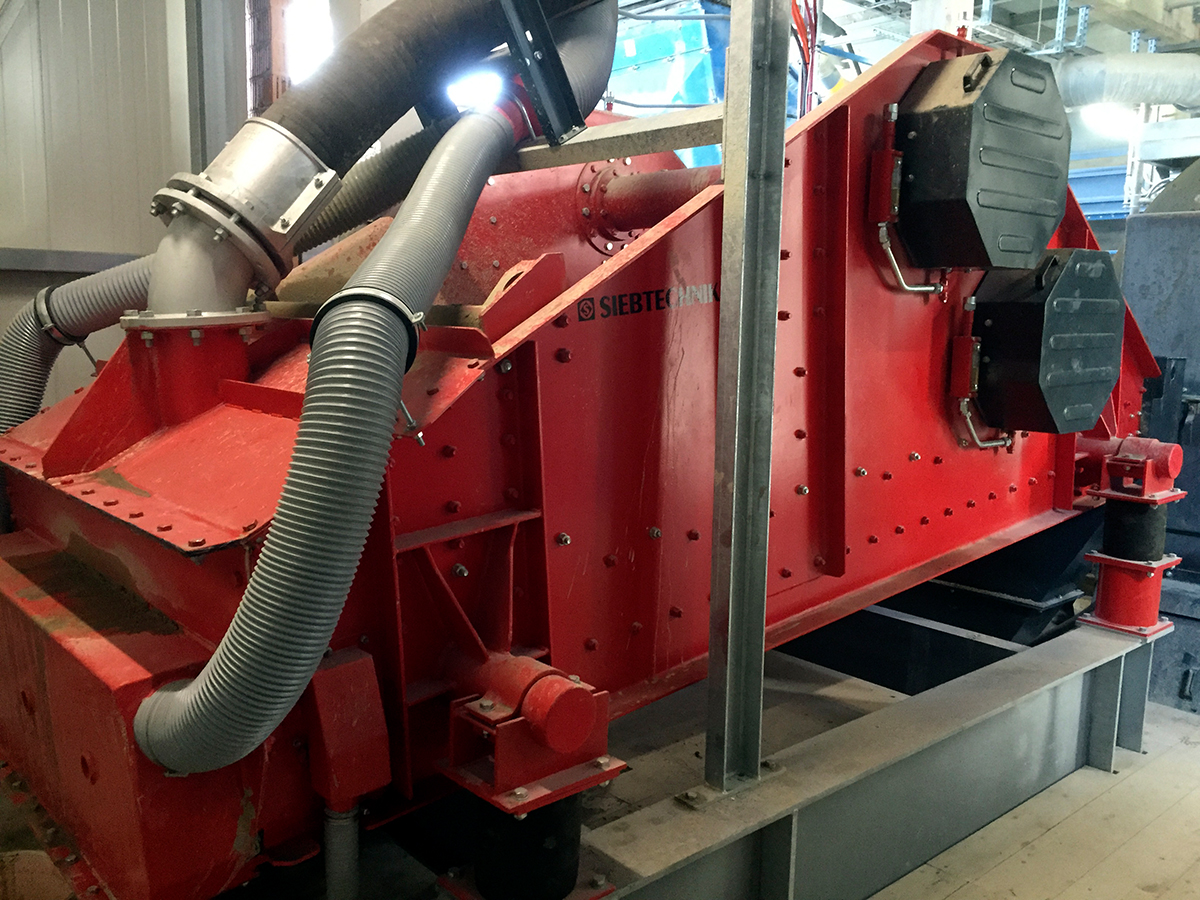

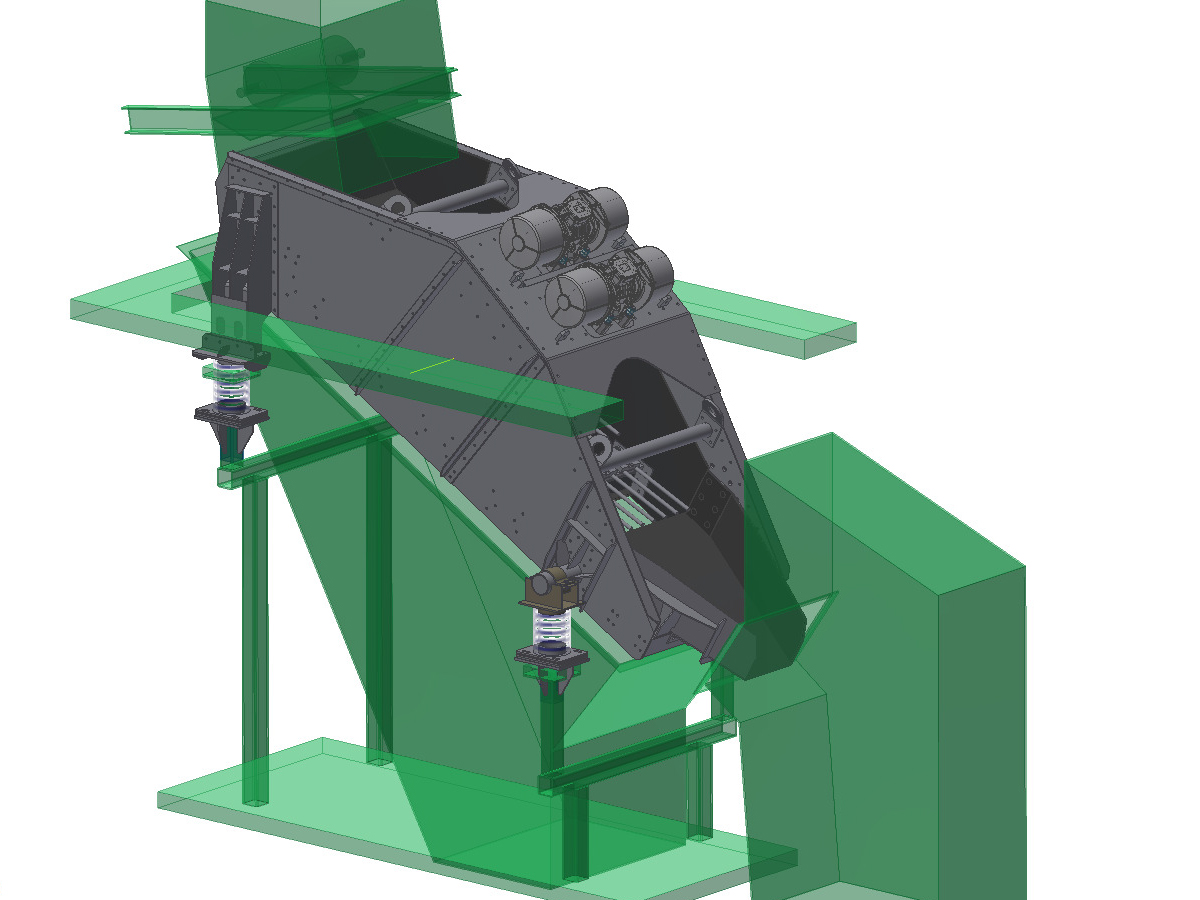

筛得力线性运动筛分机适用于粒状散装货物的筛分和脱水。由双不平衡齿轮组(HG型、HG-E型、UHG型)、双轴驱动(DWS型、DZS型、HN型)或不平衡电机(HR型、HR-E型、MHR型)提供驱动。

我们制造出带有顶部或底部安装驱动装置的线性运动筛分机,以满足极端要求。它适用于面积宽大的机器(最宽5.5m)或极大颗粒的进料(例如,边缘长度约为1.5m的花岗岩)。这些机器还可以满足高进料温度和低残留水分的要求。

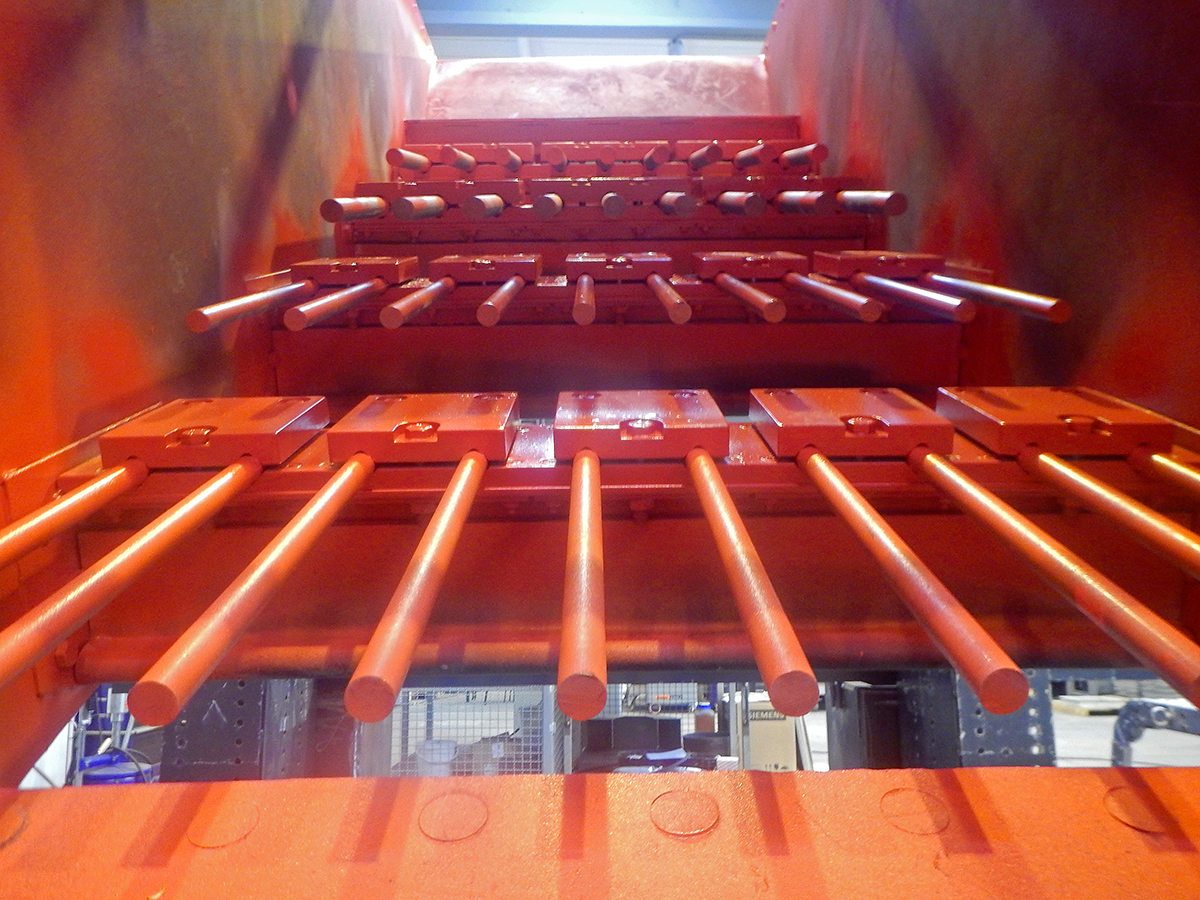

可选一层或多层式齿轮筛。不同的齿轮组尺寸可带来出色的设置,以迎合您的特定应用。平衡质量和速度可进行分阶段调整。这使得齿轮箱的线性振动幅度和加速度能够最佳地适应技术工艺要求。

线性运动筛分机的齿轮组安装快捷方便,并可提供高筛分机可用性。

我们建议将这种机型应用于破碎机减载筛分,即作为具有高进料速度或粗分离切割的初步筛分。

双轴筛

双轴筛的驱动概念基于圆周运动机器上经验证的振动发生系统,但机器有两个版本。

在其中一个版本里,两个带有不平衡块的轴承安装驱动轴以相反方向进行驱动。因此,筛箱的最终动作是线性的,就像齿轮筛一样。

我们推荐将这种驱动概念应用于在沥青生产和砂的低压脱水过程中,对温度高达450 ℃的热石屑材料进行多层筛分。

不平衡电机

双不平衡齿轮组或双轴解决方案有一个更为经济的替代方案,是由两个不平衡电机提供驱动——尤其是在标称宽度较小的区域。

两个不平衡电机以相反的方向驱动。因此,筛箱的最终运动是线性的,就像齿轮筛或双轴系统一样。这些筛孔极小的线性运动筛适用于砂、砾石、矿石、冲孔和矿渣等的脱水或再循环。

性能和机械特性

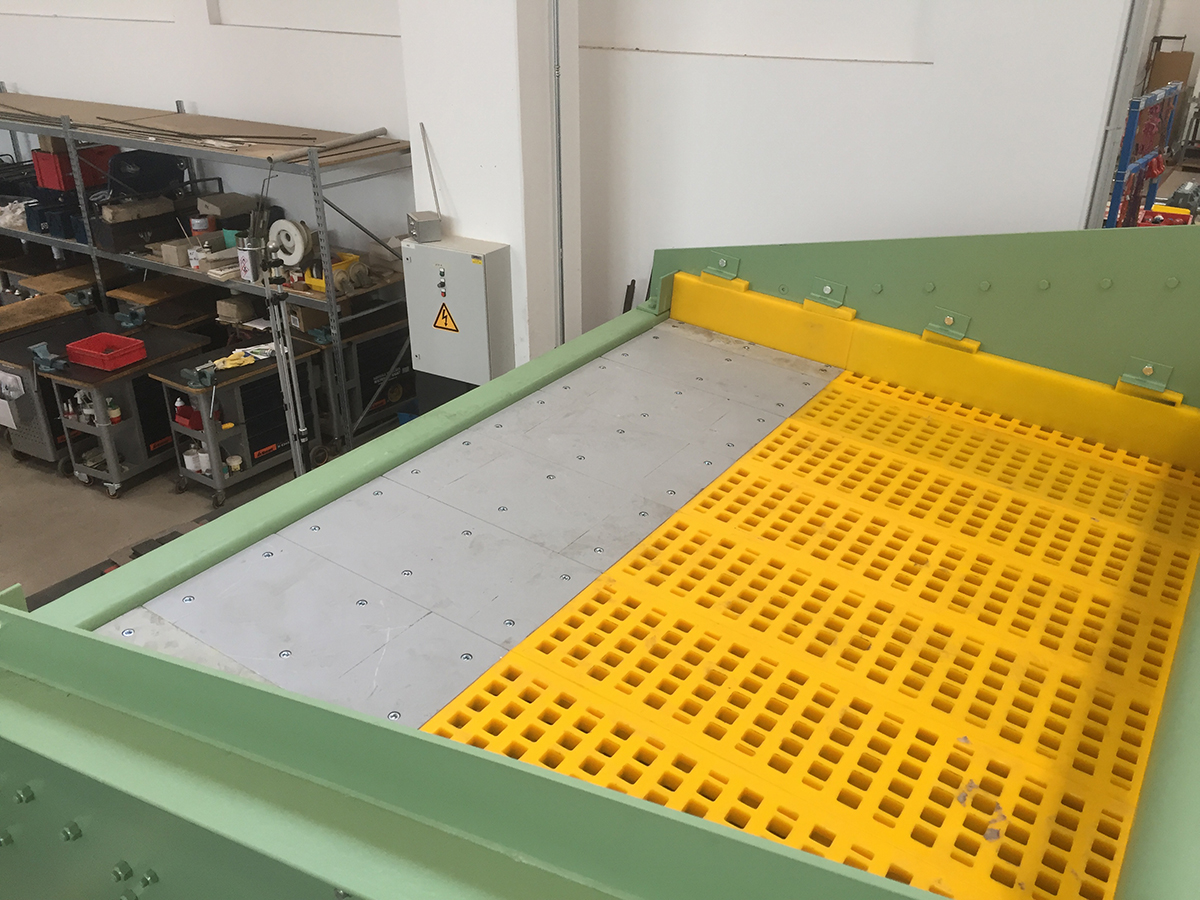

筛得力线性运动筛分机属于自由振动的筛分机,其振幅可自由调节,以适应筛箱和不平衡块的质量比。所设计的线性运动筛分机可选择性地采用陡角(大约75°)或浅倾角(大约40°),因此,我们可灵活选择筛板的倾斜度,其倾斜范围从向上至水平再到向下。例如,脱水筛需要向上倾斜3至5度,而分类筛分机需要向下倾斜高达约40°(薄层筛分)。

HG(双不平衡齿轮组)、DWS(双轴筛)和HR(不平衡电机)系列筛分机的分离尺寸在0.5至300mm之间,筛分面积在大约0.1至60m²之间。根据所用产品的不同,这些机器的振动幅度可在2到14mm之间进行设置。筛网装置可由一至三个筛面组成。

该线性运动筛分机的速度和振动幅度可根据产品的具体情况进行调整,从而确保获得持久完美的筛分结果。

筛箱可选用纵向或横向张紧的筛板,或适用水平筛面,也可适用第三方制造商生产的筛网。

由侧壁和横梁组成的筛箱能够承受所有的静态和动态力。振动产生系统不在筛箱的重心位置上。双不平衡齿轮组或不平衡电机安装在驱动桥上。重要的是,其合力的方向穿过重心。这同样适用于双轴筛分机上两个驱动轴的位置。

线性运动筛分机由具有中间传动的三角皮带传动所驱动,或通过万向节轴的直接传动所驱动。双不平衡齿轮组有一个注油口。不平衡电机始终采用油脂润滑。双轴筛网可选择使用油润滑或油脂润滑。

筛箱由4个弹簧元件弹性支撑在底座上。在这里,螺旋压缩弹簧、橡胶缓冲器、振动元件或风箱的不同系统均是可用的,并且如有需要,可以组合应用(混合式悬挂)。

对于含尘物料,我们可根据需要提供带有防尘罩或封闭式防尘箱的线性运动筛分机。也可采用搅打装置或喷洒系统的形式,单独适用筛分辅助设备。

该坚固结构与标准部件组合应用,一方面确保了高度的灵活性和以客户为中心的解决方案,另一方面也使得所制造的机器具备低维护运行时间和长使用寿命的特点。

技术规格

| 线性运动筛分机 | |||||

|---|---|---|---|---|---|

| 有效宽度 | mm | from | 600 | up to | 5500 |

| 有效长度 | mm | from | 1000 | up to | 12000 |

| 倾斜度 | degree | from | 5 | up to | -30 |

| 速度 | min-1 | from | 750 | up to | 1200 |

| 振幅 | mm | from | 2 | up to | 14 |

| 投掷角 | degree | from | 40 | up to | 75 |

| 振动重量 | t | up to | 40 | ||

低压脱水筛分机

如果需要满足低残留水分(如对于沙子)的特殊要求,低压脱水筛分机是一个不错的选择。与通常用于脱水的直线运动筛分机相比,低压脱水筛分机能提供更低的残留水分性能。该机器基于“双轴筛分机”的驱动概念,由于产生了这样的振动,它可以获得更高的速度。气动低压系统速度的提高,对残留水分水平有着显著的降低作用。

筛得力低压脱水筛分机具有以下优点:

- 客户定制

- 高脱水性能

- 适用于筛选材料的筛网

- 低堵塞脱水

- 出色的隔振性能

- 稳健设计

- 组件经过长使用寿命时间测试

- 优化的适用驱动概念

- 低维护、易于维修

热标准筛分机

为了制造标准沥青粘合基层和表面层,可采用固定式、半移动式或移动式沥青混合系统。这些设备主要由干燥滚筒、斗式输送机、筛分机、集料仓、称重和混合设备以及装运装载系统构成。

骨料约占沥青配方重量的80%至90%,它们将在由燃烧器加热的干燥滚筒中加热至所需的温度。沥青层的质量取决于粘结材料的质量和最大体积组分粒状骨料的正确粒度组成等因素。因此,筛分机尤为重要

筛得力NH型筛分机的优点是,驱动装置安装在固定防尘罩的外面,即位于加热区的外面。在许多应用中,我们已采用该系统对温度高达450℃的热碎屑进行了可靠的筛选。

在这里,正确选择筛网和筛网的张紧条件也很重要。

机器的卓越性能与防尘罩相配合,能够快速降低温度,这是维护或维修时缩短停机时间的重要要求。自2001年以来,新的分离式防尘罩设有完全可延伸的斜槽托架,这是对早期系统的进一步改进。

筛得力热标准筛分机具有以下优点:

- 客户定制

- 组件耐温

- 适用于筛选材料的驱动系统、筛箱和筛网

- 紧凑设计

- 低堵塞分类

- 出色的隔振性能

- 稳健设计

- 组件经过长使用寿命时间测试

- 优化的适用驱动概念

- 低维护、易于维修

专用筛分机

为尽可能多的应用提供筛分设备多年来一直是我们生产范围的一部分。

即使筛选问题看似无法解决,也可以向我们咨询意见。筛得力拥有训练有素的工程师团队和近100年的行业经验,竭诚为客户服务。

筛分机的附件

所有筛得力筛分机均配有一系列附件可供选择。无论是定制喷涂、防磨装置、防振架、空气悬架、防尘罩、防尘盖、驱动控制台、双不平衡齿轮装置、混合悬架还是特殊的筛网,凭借其数十年的经验,我们均能为客户提供符合客户要求的最佳设备搭配。

所有的附件都与筛分机完美适配,并配套为客户提供最佳的服务。

Application

- 针对客户需求的的定制化概念

- 可具有较大机器宽度

- 可装载大颗粒和粗颗粒

- 高筛分性能和高脱水性能

- 适用于特定筛分材料的多种筛网

- 几乎可以使用所有市售的第三方筛网

- 优秀的筛分效果

- 即使带有粗糙的分离切口也较少发生堵塞

- 分类时分离精度高

- 良好的减振性能

- 稳固设计

- 组件通过长寿命时间测试

- 驱动适应性高

- 低维护和易于维修

- 可以集成到现有装置中